About Juzheng

Dongguan Juzheng Electronic Technology Co., Ltd,was established in 2006, is a high business ethical company based the headquarter in Dongguan,Guangdong ,China. We specialize in developing automatic packaging, identification and detection technology. After more than 15 years development, Juzheng owns two workshops and two production lines as follows:

1. Automation Equipments

Multi-head weigher, Vertical Form Fill Seal Machine, Metal Detectors and Checkweighers. These machines are typically used for packaging, detecting various metal impurities and weight abnormality in food, beverage, pharmaceutical and plastic industries.

2. X-ray Inspection System

X-ray Inspection Systems for food, industries and baggage. These machines are often found in public places, government departments, large-scale security and industries NDT(Nondestructive Testing) inspections.

Advantages of Juzheng

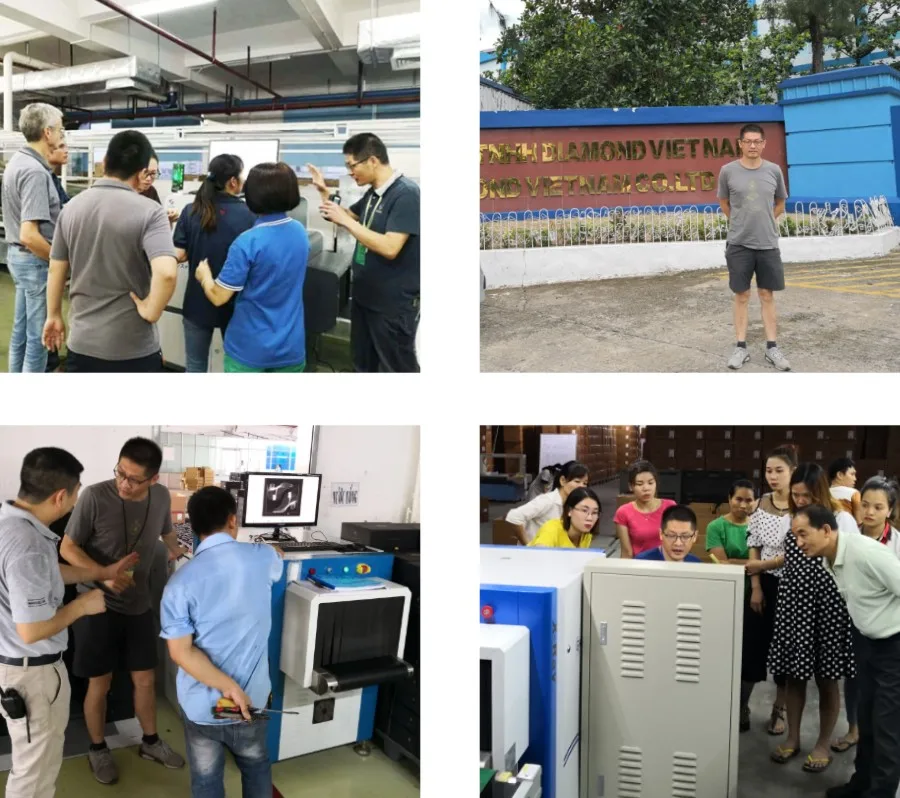

1. Experienced Technician Team

Juzheng has a technicians team with more than 15 years of experience in the development and production of X-ray inspection and automation equipments.

2. Strict Quality Control

Juzheng strictly abides by the international standards of ISO9001, ISO 14001 and OHSAS 18001. Meanwhile, we implement a strict quality control system and supervise all production processes from feeding, processing, installation, debugging to delivery. At present, Juzheng has obtained the CE, PVoC certificates and passed the audit by TUV.

3. Top brand of components

Juzheng adopt well-known brands of components from China, Japan, France and German to ensure product quality from the source.

- Solid State Relay is from France

- Intermediate Relay is from Japan

- PLC, Screen, Inverter, Load Cell, Servo Motor and Servo Drive are from German

4. Professional sales team

Juzheng sales team has an average of more than 8 years of experience in product marketing and after-sales services.

Juzheng Service SOP

Pre-sales Services:

1. Collecting customer’s product information and requirement.

2. Providing solution and offer for customer’s review 12 Hours after information collection.

3. Hundreds of service cases and videos will help our customer to understand our machine better.

In-sale service:

4. Sending the machine drawings for customer’s approval before mass production.

5. Following up each production process to make sure on-time delivery.

6. Sending the machine inspection video for customer’s approval before delivery.

7. Working with forwarder for the shipping and keep the customer updated on ETD & ETA.

(Multi-head weigher and packaging machine drawing)

(Metal detector drawing)

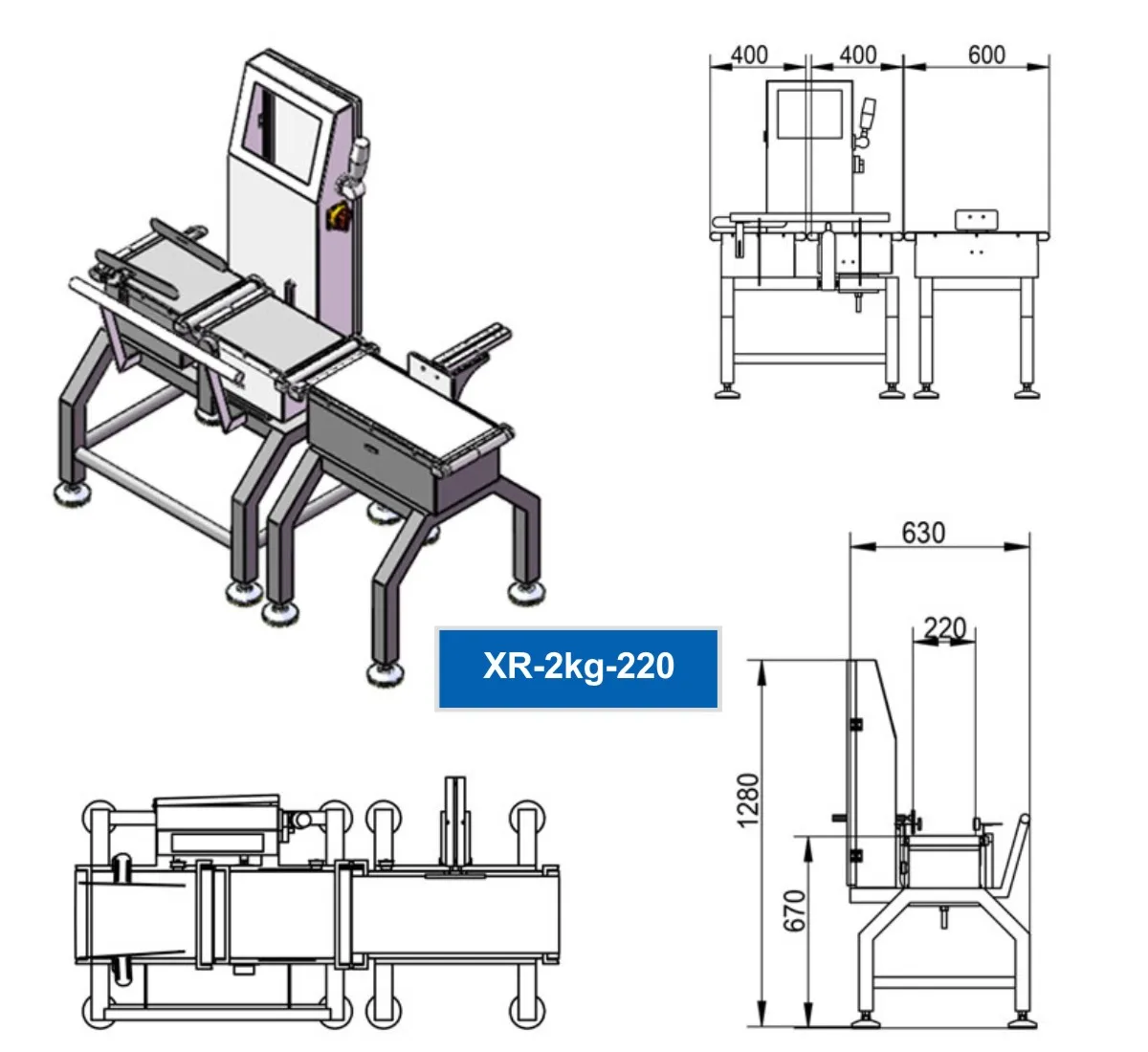

(checkweigher drawing)

(X-ray inspection system drawing)

After-sales service:

8. Manules / Videos of machine installation, adjusting, setting,maintenance are available for our customers.

Online after-sales service:

9. We will give response in 4 hours in case of machine failure, solutions will be offered in 24 hours via whatsapp,wechat and facebook. What’s more, our engineer team can speak English, which can communicate more effective.

Onsite after-sales service:

10. If there is a need,we can arrange our engineer to your place for technical support.

Main spares replacement:

11. We store main spare parts at our warehouse, if need to change the accessories, you can receive it easily around 5-7 days by courier.